Creep & stress rupture testing can be conducted under constant load or consatant stress. The differences are described as follows:

1) Constant Load

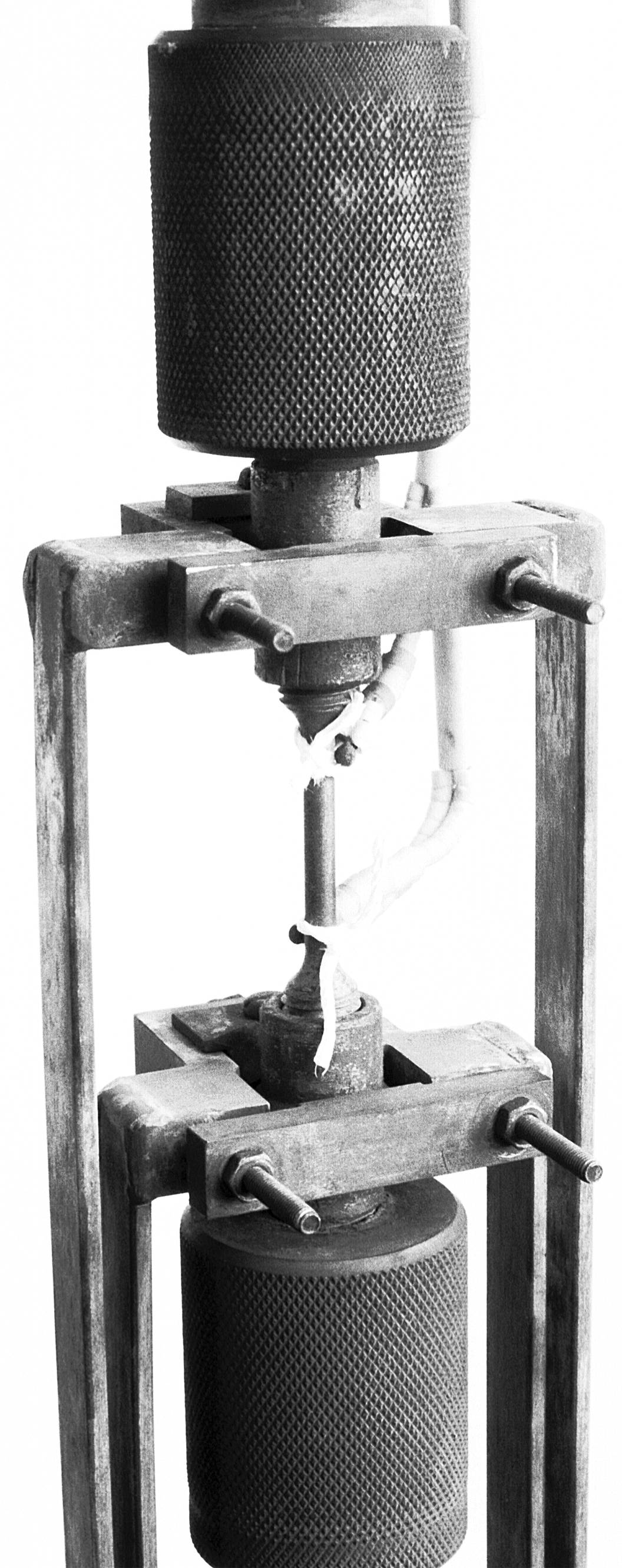

Constant load testing is performed on a machine with a straight lever arm. As the specimen elongates, the capstan on the frame automatically adjusts to maintain the lever arm in the horizontal position, keeping the load application at a fixed length along the lever. If the auto-levelling facility wasn’t present, the test would not be under a constant load or constant stress condition.

2) Constant Stress

Constant stress machines have a curved lever or cam. Unlike the constant load machines, the frames do not have any automatic levelling to the cam. Instead, as the cam lowers, the distance of the applied load from the pivot is reduced and therefore the force acting on the specimen decreases. The design of the cam (i.e. curvature) is such that the drop off in load is proportional to the reduction in cross section of the specimen and hence maintains a constant stress on the test piece. The machines at SMaRT are designed to work on a specific specimen geometry with a 1” gauge length. If you require constant stress creep testing, please enquire about the specimen design.

SMaRT routinely conducts creep or stress-rupture testing in compliance with the following international and industry standards (working to other standards are available upon request):

- BS EN 2002-005 Metallic materials – Aerospace series – Test methods for metallic materials – Part 005: Uninterrupted creep and stress-rupture testing

- BS EN ISO 204 Metallic Materials – Uniaxial creep testing in tension – Method of test

- ASTM E139 Standard test methods for conducting creep, creep-rupture and stress-rupture tests of metallic materials