05/06/2025 – SMaRT announced as partner for IOM3 M3P3 event

We’re excited to announce that Swansea Materials Research and Testing Ltd (SMaRT) will join IOM3 as an academic partner for their flagship M3P3 event being held in Birmingham Nov 11-12 2025. The event will explore themes such as AI, the circular economy, sustainability, and the impact of materials, minerals, and mining on people, places, and the planet.

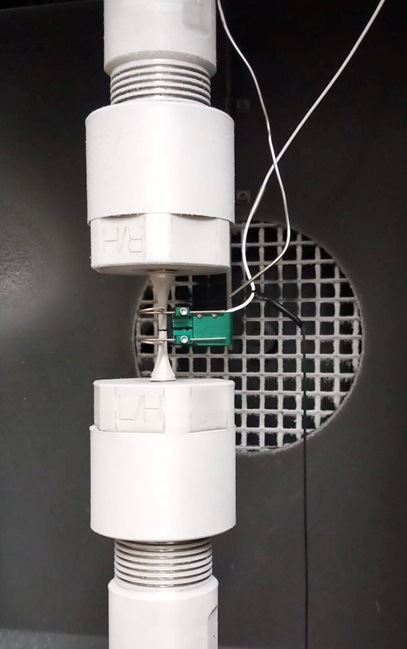

26/11/2024 – Bend fatigue testing of pipe sections

We’ve pulled out our lovely Instron 4 point bend fittings to run some load controlled fatigue tests on pipe sections. The intention is to compare fatigue results from welded sections with that of the virgin pipe (pictured). Our friends at Swansea University helped 3D print some guides to prevent any sideways movement of the specimens whilst on test.

10/10/2024 – Miniature bend testing

We’ve been asked to run a package of bespoke 3 point bend tests on miniature specimens. The test specimen is only 3mm thick and less than 30mm in length. We’ve had to design and manufacture a specific jig to enable us to run these tests. It’s a great example of the quality and precision of the work from our on-site machine shop here at SMaRT.

01/10/2024 – Fatigue testing of adhesive bonds.

We’re currently running a package of tests for one of our valued customers that’s a little unusual; fatigue testing of adhesive bonds. We’re testing over a range of loads to generate F-N curves on different bond assemblies. The data we’re collecting is surprisingly clean, with very little scatter.

15/03/2024 – JOSCAR registered

SMaRT has satisfied all the requirements to become fully registered on the JOSCAR supplier accreditation register. This allows us to offer our testing services to a range of participating organisations in the aerospace, defence and security sectors.

23/02/2024 – Cryogenic testing facility

SMaRT now has a designated cryogenic test frame. The environmental chamber uses liquid nitrogen to control the test temperature for sub-zero applications. To date we’ve successfully used it down to -150°C, with a specific cryogenic extensometer, for tensile testing. With different fittings other test types can also be performed. The frosty image below is cheating slightly. On test there is no frost. We opened up the chamber after the test to allow ‘moist’ laboratory air into the chamber for dramatic effect!

22/02/2024 – SMaRT sponsors the EIS Fatigue 2024 conference

We are please to announce that SMaRT is sponsoring the 9th Engineering Integrity Society International Conference on Durability & Fatigue, taking place at Jesus College, Cambridge on 19-21 June 2024.

click the following link for more details:

https://fatigue2024.com/conference-information-brochure/

22/02/2023 – SMaRT obtains Cyber Essentials Plus Certification

SMaRT now holds Cyber Essentials Plus certification to provide our customers with the assurance that we keep your data safe from common forms of cyber attack.

06/02/2023 – SMaRT obtains Cyber Essentials Certification

SMaRT now holds Cyber Essentials certification to provide our customers with the assurance that we keep your data safe from common forms of cyber attack.

29/04/2022 – Bespoke Testing of Wiring Harnesses

This week we have been performing some unusual bespoke tests for a customer. We’ve been conducting tensile pull testing to determine how well the fastening clips grip the wire harness before slipping. This is just one example of how we can assist customers with our bespoke testing capability to meet their needs. If you have anything we may be able to assist you with please feel free to get in contact.

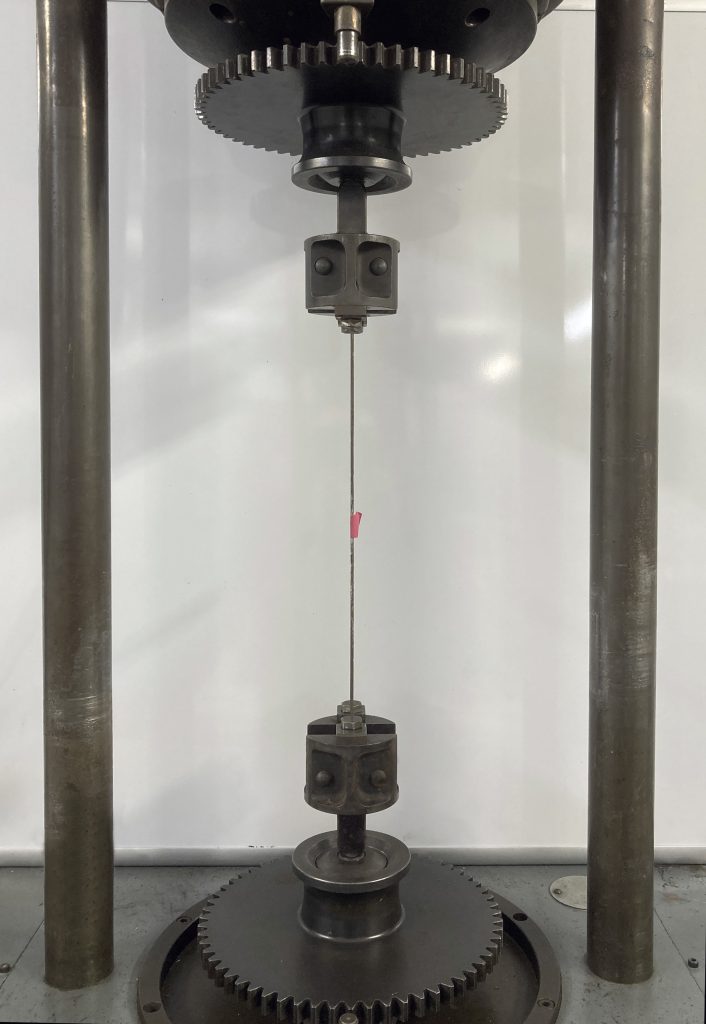

08/02/2022 – HCF Testing of Wires

SMaRT can now offer high cycle fatigue (HCF) testing of wire specimens using our Vibrophore test frames.

Using our specially designed grips to spread the clamping pressure, to ensure fracture occurs away from the grips, we can test wires/rods of up to 6mm diameter. The frequency of testing will be dependant on the stiffness of the samples. The same grips can be used on a universal test frame to run tensile tests or low cycle fatigue (LCF) testing.

19/01/2022 – ISM/SMaRT promotional video

The Institute of Structural Materials (ISM) has released a promotional video featuring the SMaRT laboratories and detailing the unique collaboration between the two parties.

The Institute of Structural Materials (ISM) is a world leading academic research and teaching facility at Swansea University. The ISM focuses on high performance materials for structural applications with expertise in extreme environments.

The ISM works alongside Swansea Materials Research and Testing Ltd (SMaRT) to provide mechanical testing solutions to a wide range of industries. SMaRT acts as a commercial testing company and operates modern test laboratories with UKAS ISO 17025 accreditation. A wide range of test types can be undertaken including tensile, fatigue and creep testing under different loading conditions, temperatures and environments.

The unique collaboration between commercial and academic facilities allows for investigation of materials through different routes including commercial testing or supported by the academic team in the form of fast turnaround consultancy, longer term postdoctoral research, or PhD programmes. The team are happy to advise on appropriate routes, and to support development of test programmes.

Enquiries are welcomed to either ISM Director Prof Mark Whittaker (m.t.whittaker@swansea.ac.uk), or to SMaRT (smart@swansea.ac.uk)

16/07/2021 – Specimen Machining

SMaRT are please to announce that we are now able to offer machining of test specimens in our on-site mechanical workshop. This offers efficiency improvements, as specimens can go on test as soon as they are produced, rather than waiting for them all to be machined and then sent from the manufacturer to the test house.

26/04/2021 – Novel Fatigue Testing

SMaRT now has a guest blog on the Swansea University Metal project website.

Check out one of our more unusual mechanical testing programmes; fatigue testing of gum shields.