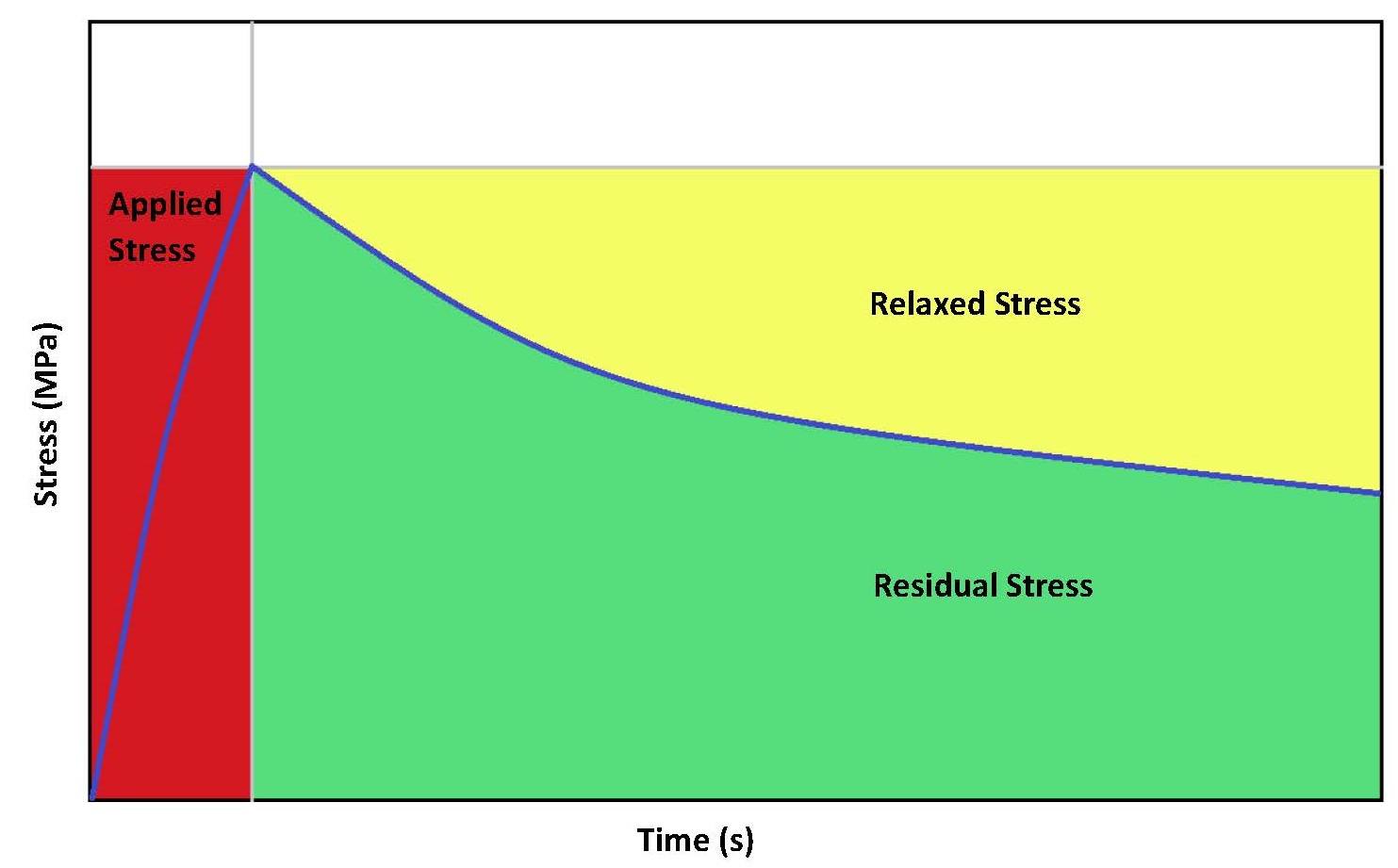

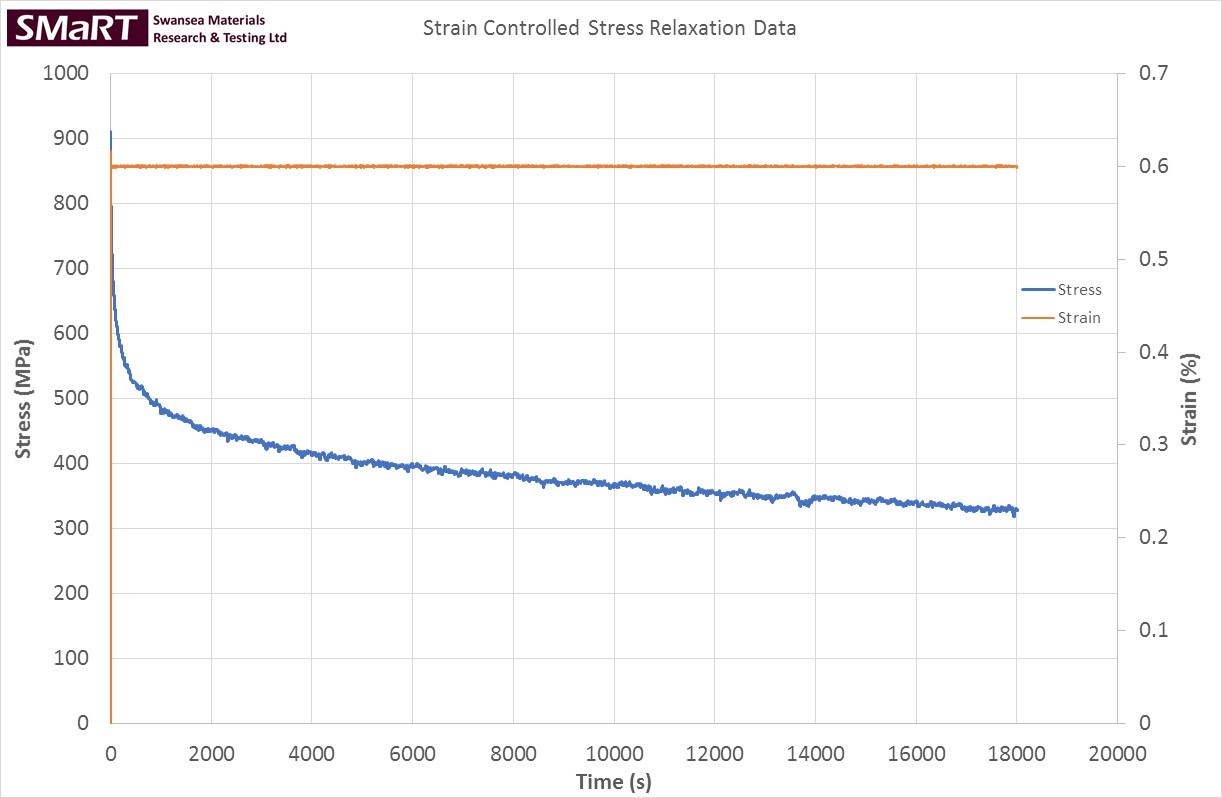

Stress relaxation testing to assess the behavior of materials involves stretching specimens, by applying a load ramp, to a pre-determined value, using a device at elevated temperature. The device is then switched to strain control (or stroke control, using the position of the machine crosshead) to hold the specimen at a constant strain/elongation. The temporal drop of the stress is then monitored for the required duration fo the test. The characteristic value obtained from the test is called the relaxation stress.

SMaRT routinely conduct stress relaxation testing in compliance with the following international and industry standards (working to other standards are available upon request):

- ASTM E328-13 Standard Test Methods for Stres Relaxation for materials and Structures