The majority of test frames at SMaRT are fitted with a furnace for high temperature operation. Accurate temperature control is critical for delivering high quality testing in compliance with the required test standards.

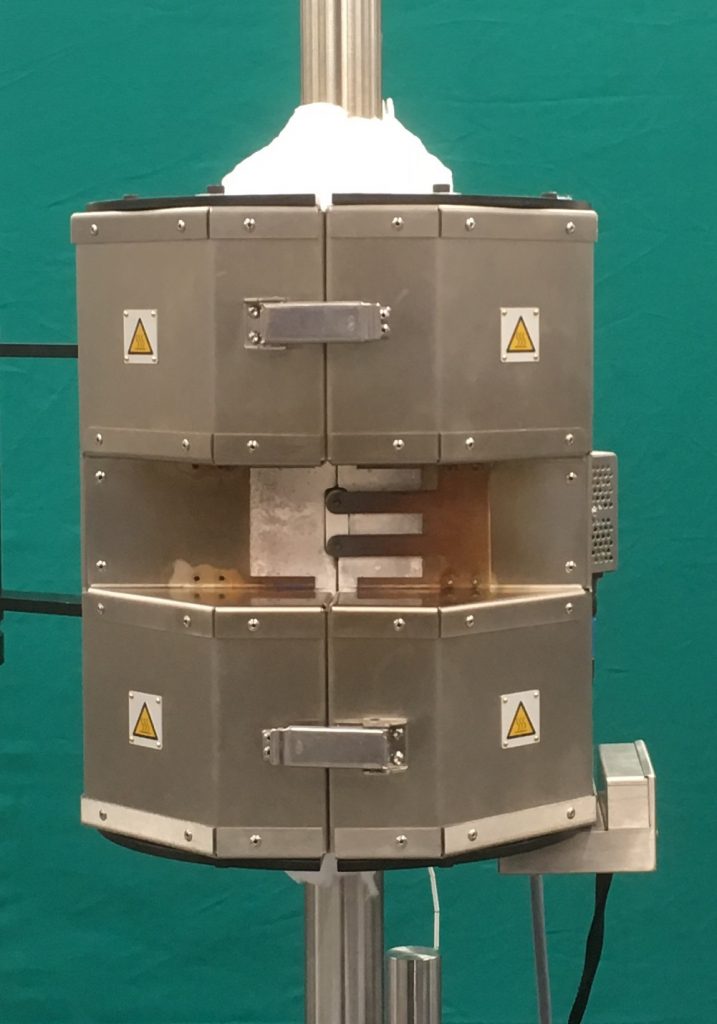

Typically, three zone cylindrical resistance furnaces are fitted to creep frames, whilst a split design cylindrical furnace is used on the universal test frames, to facilitate loading. These furnaces operate up to temperatures around 1000°C.

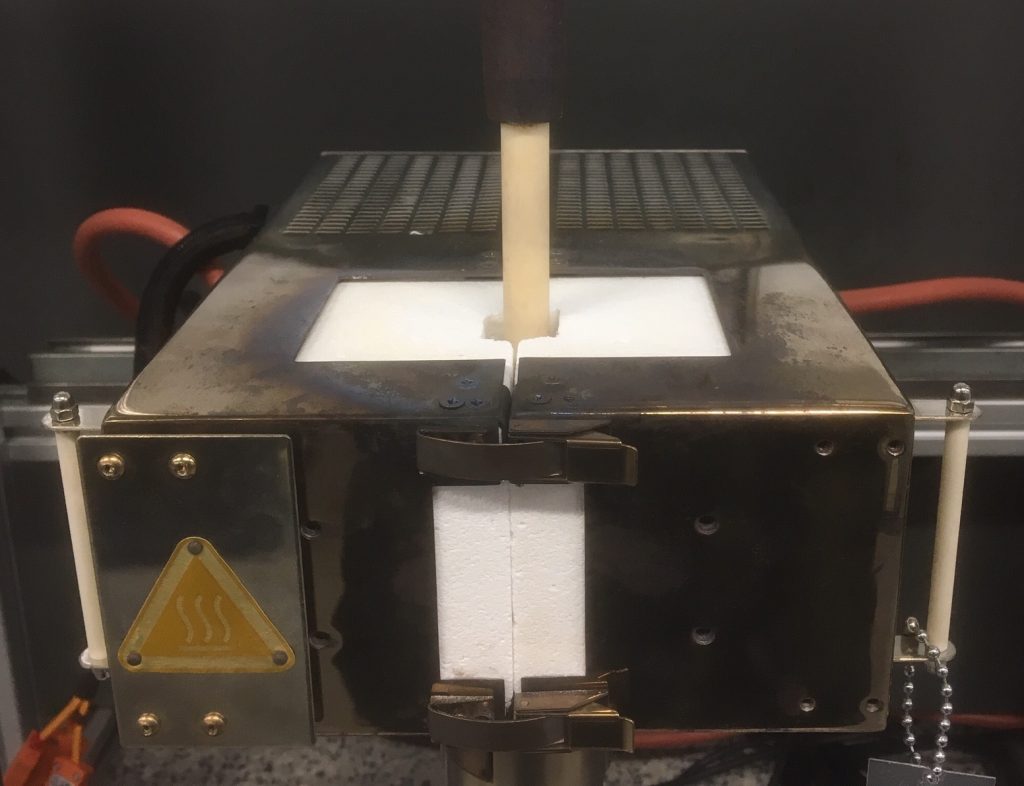

Additionally, SMaRT has a number of smaller split box furnaces capable of temperatures of 1300°C, which are also useful for applying accurate temperature control to a small test section.

A limited number of machines are equipped with induction heating systems which can apply a very precise heat affected zone. These are primarily used for thermo-mechanical fatigue testing.

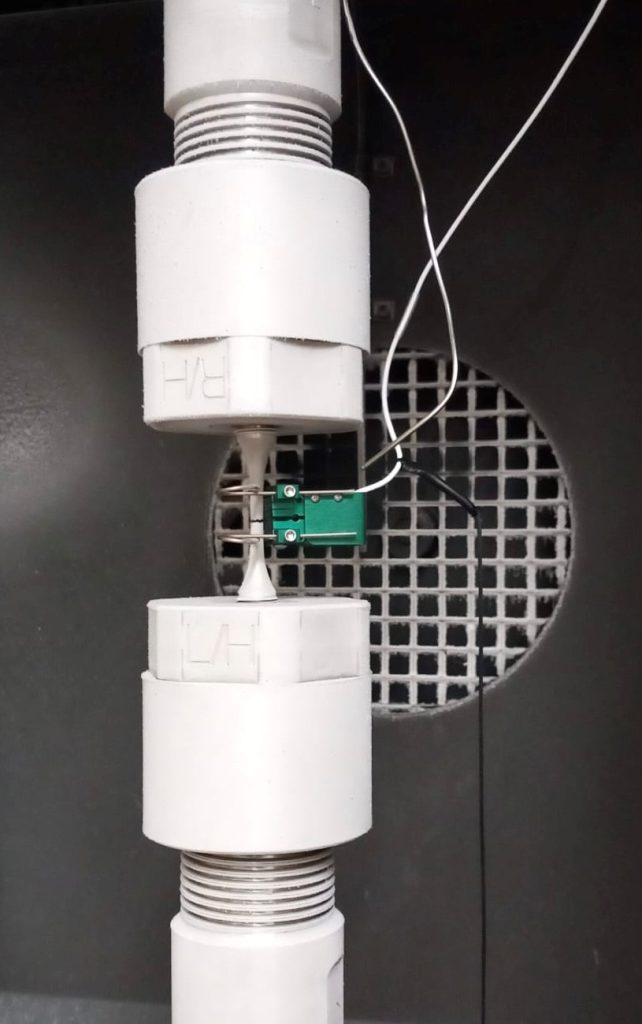

SMaRT now offers a designated cryogenic test facility. The test frame fitted with an environmental chamber uses liquid nitrogen to control the test temperature for sub-zero applications. To date we’ve successfully used it down to -150°C, with a specific cryogenic extensometer, for tensile testing. With different fittings other test types can also be performed.

Cryogenic Tensile Test

SMaRT also has a suite of bench mounted furnaces for heat treatment of specimens . Furnace conditions close to the specimens are monitored with type N thermocouples connected to digital displays.