Typical material properties which can be measured using tensile testing are:

1) Elastic Modulus

The Elastic Modulus (or Young’s Modulus) which is determined by the ratio of stress to strain below the elastic limit. The Modulus of Elasticity measures the stiffness of a material, but it only applies to the portion of the test where the ratio of stress to strain is constant, i.e. the straight-line portion of the stress/strain graph prior to the beginning of the curve. At this point in the test, if the load is removed, the test specimen will return to its original condition. After this point in the test, plastic deformation begins to occur, and therefore the test specimen will not return to its original proportions upon relaxation of the load (i.e. it has yielded).

2) Ultimate Tensile Strength

The Ultimate Tensile Strength (UTS) is determined by dividing the peak load achieved before rupture by the original cross section of the test specimen. Yield Strength is determined by the amount of stress that is required to begin plastic deformation of the test specimen.

3) Proof Stress

Proof Stress is the stress at which a non-proportional extension is equal to a specified percentage of the extensometer gauge length. Typically, 0.2% proof stress is reported (i.e. the stress achieved at 0.2% strain). To determine the 0.2% proof stress, a line is drawn from 0.2% strain with the same slope as the Modulus of Elasticity. The stress value at the intersection of this line with the stress/strain plot for the test provides the required proof stress.

4) Elongation

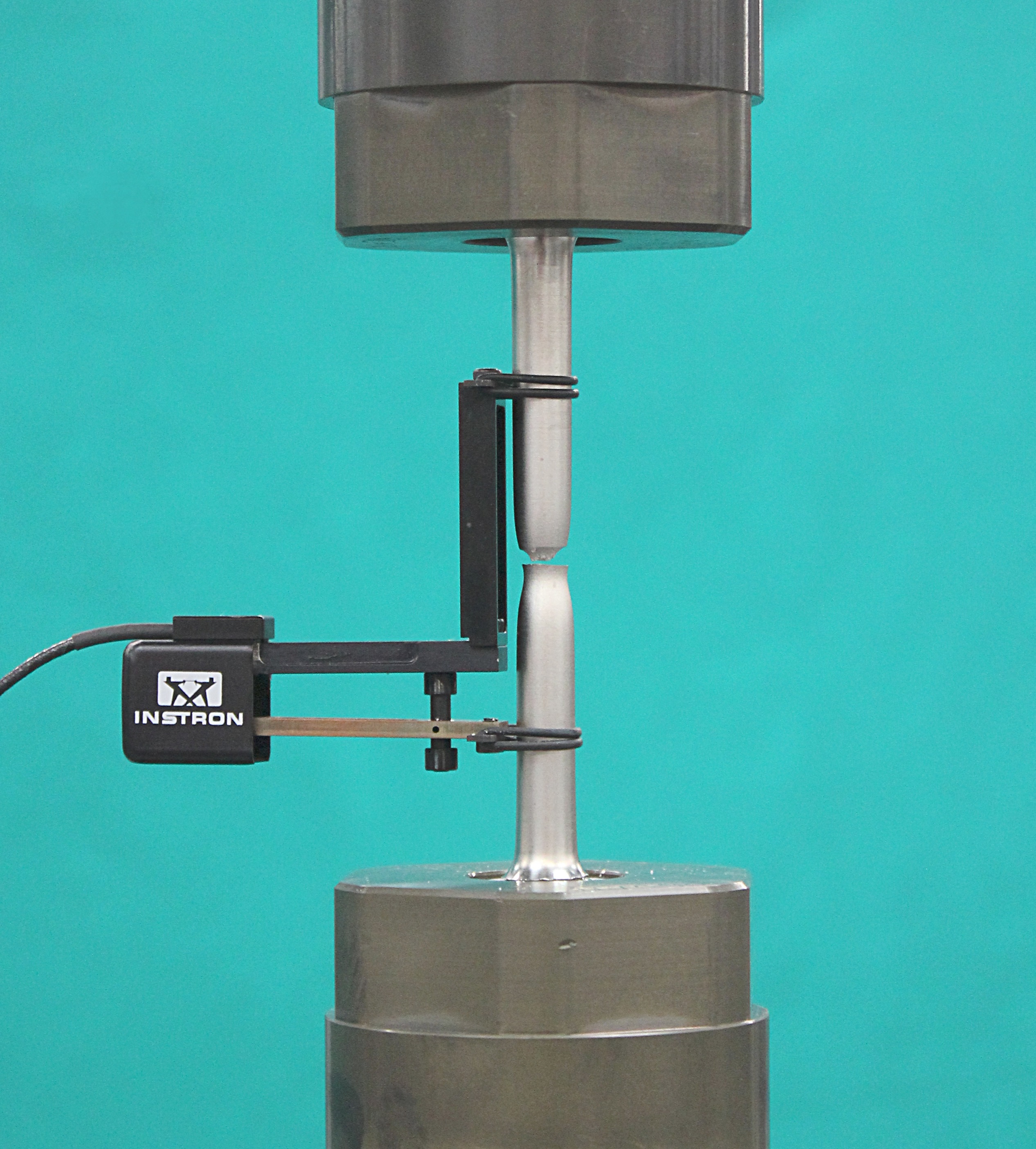

The Elongation can be reported from two methods. Elongation At Rupture can be measured if the extensometer can stay on the specimen until fracture (dependant on the degree of travel of the extensometer). Alternatively, Elongation After Rupture can be measured by physically fitting the broken parts of the specimen back together post test and measuring the increase in gauge length (with pre and post test measurements taken at ambient temperature). Both forms of elongation are reported as a percentage of the original starting gauge length.

SMaRT routinely conducts tensile testing in compliance with the following international and industry standards (working to other standards are available upon request):

- BS EN 6892-1 Metallic materials – Tensile testing Part 1: Method of Test at ambient temperature

- BS EN ISO 6892-2 Metallic materials. Tensile testing. Method of test at elevated temperature

- BS EN 2002-1 Aerospace series. Metallic materials. Test methods. Tensile testing at ambient temperature

- BS EN 2002-2 Aerospace series. Metallic materials. Test methods. Tensile testing at elevated temperature

- ASTM E8 Standard test methods for tension testing of metallic materials

- ASTM E21 Standard test methods for elevated temperature tension test of metallic materials